INDISOL have been requested on many occasions by Business leader’s to provide insights on how they can ascertain if their LUBRICATION activity and programmes are working, to maximise productivity and extend asset life and how to best measure performance.

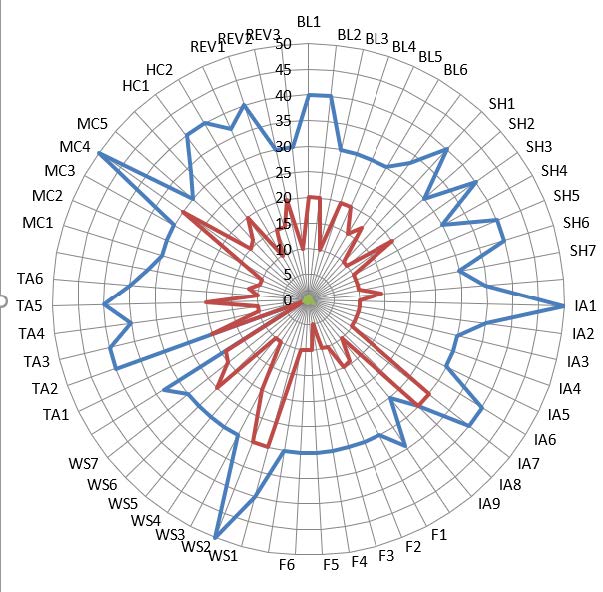

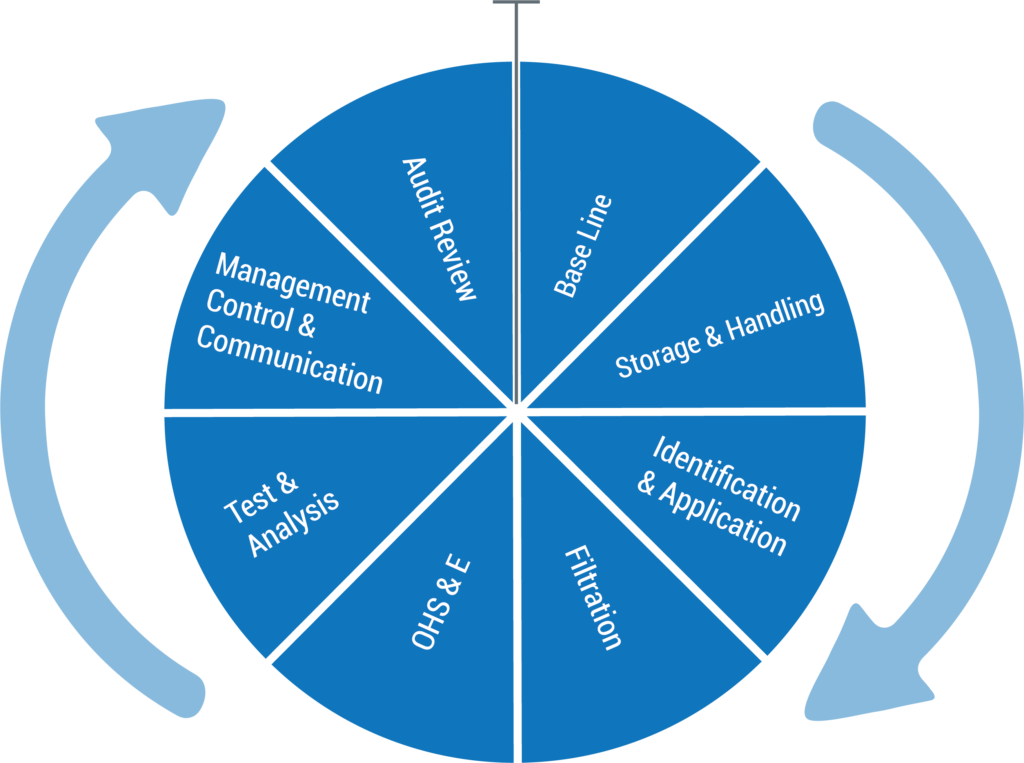

INDISOL designed and developed its LUBRICATION ASSET MANAGEMENT SYSTEM, LAMS to meet this need.

It is a comprehensive system covering all competence areas for a LUBRICATION SYSTEMS which is a closed loop, starting at set up and ending at reviews and continuous improvement philosophy’s all aimed at reducing cost while increasing performance.

Base Line This in simple terms is a Lubrication Survey of each and every lubrication point on a machine’s in a plant. It is aimed at identifying every one of the 6

of 6 “R”. This starts with:

A lubrication survey which details all lubrication needs:

If you undertake this exercise for all you equipment in your plant and the relevant application points, you will be on the road to cutting cost of failure in efficient operations down time loses.

INDISOL specialise in supporting and assisting with Lubrication Surveys for all plant types including Mining, Food Grade sites and even complex Nuclear plant

Storage and handling – This says it all, the decision to purchase Lubricants (Oils & Greases) and cleaning agents, presents storage and handling needs and challenges. There is an

Australian Standard you will need to ensure you adhere to, but there are also Petroleum Industry Guidelines for developing a Best practise approach.

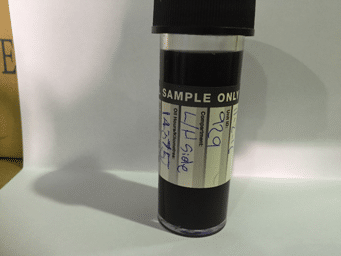

DIRTY contaminated Oils and greases more often than not cause failure. You only need to care and it is not costly to do it right, but IT DOES eliminate WASTE. INDISOL assist and support Best Practise Solutions.

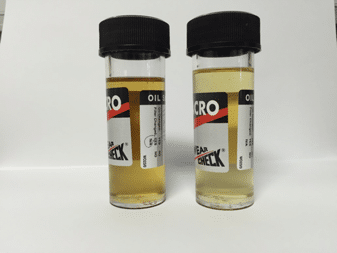

Click the pictures below to enlarge.

Identifying lubricants can often result in wrong application being made even in best organised industrial plants. Often thi s is associated with changes in people doing the lubrication tasks and not being familiar with WHAT goes WHERE. It also pays to set your system up without reference to product BRAND NAMING. If you ever deci de to change suppliers you avoid confusion of change and incorrect lubricants application.

INDISOL have worked with Customers to designs a SITE Specific Identification & Application system in association with our label publishers

It is a fact that if you filter lubricants you not only benefit from an extended life of the fluid but also compone nt wear is reduced reducing requirement for working capital to repair and

refurbish equipment. This applies to Dry Filtration of air breathing into compartments and wet filtration by way of BY PASS Filt ration (Kidney Loop Filtration). INDISOL specialise in supporting Customers to set up innovative filtration solutions which pay for themselves in acceptable pay back timeframes. Give INDISOL a call an d s tart to reduce Operating costs and improve you productivity by removing wear metals, contaminants and dirt.

Occupational Health, Safety & Environment, must be a key consideration when working with Lubricants and Lubrication Systems.

The more emphasis placed on a “Cradle to Grave” philosophy, will ensure that every effort is made to safe guard your, Staff, Asse ts and the environment you activity impacts on. It starts again with you Lubrication Survey and moves through all aspects of the lubrication system activity right until you dispose of spent and waste oils and greases. By example INDISOL approach the systems by;

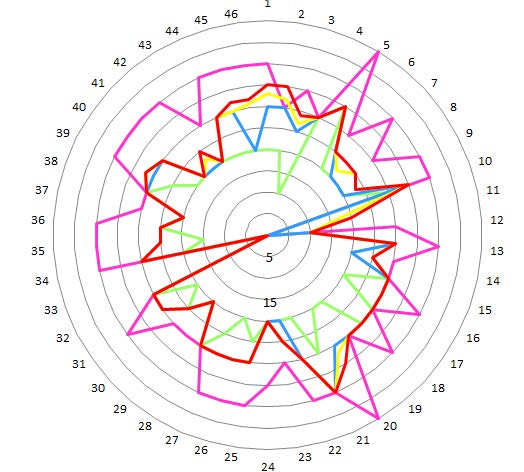

Oil Condition Monitoring has over decades proved to be an invaluable Tool for monitoring condition of both Fluids and Equipment. Unfortunately understating reports and what result mean are poorly understood or communicated. INDISOL continue to service Industry of various market sector with in de pth diagnostics and recommendations on findings. This has resulted on respect form our customers. Oil Condition Monitoring is a simple tool with capacity to save substantial amounts of money.

Click here to see a Wear Check

All foreword thing and progressive Business leader look for ways to set goals for the various team structures including M aintenance and Production. Providing a tool to allow Leaders to set Lubrication performance goals and then measure the outcomes using S.M.A.R.T principles is a strength for LAMS and its custome rs. This is supported by Audit reviews undertaken at fined time intervals setting a foundation for Continuous Improvements.

We earlier stated Captain of Industry and Business leaders, as part of the business process set Goals and objectives and then seek to review the Business performance against these.

GREASE

DESIRED VISCOSITY @40°c

KAPPA RATIO VISCOSITY @40°c

ISO VG 460/1.5

460 cSt GRSE

460

KAPPA RATIO LOW

60

8

KAPPA RATIO HIGH

220

2.1

ISO VG 220/2

233cSt GRSE

233

KAPPA RATIO LOW

60

3.9

KAPPA RATIO HIGH

220

1.1

ISO VG 400/2

400~450 cSt GRSE

450

KAPPA RATIO LOW

60

7.5

KAPPA RATIO HIGH

220

2.05

ISO VG 135/2

135 cSt GRSE

135

KAPPA RATIO LOW

60

2.3

KAPPA RATIO HIGH

220

0.61

ISO VG 150/2

150 cSt GRSE

150

KAPPA RATIO LOW

60

2.5

KAPPA RATIO HIGH

220

0.68

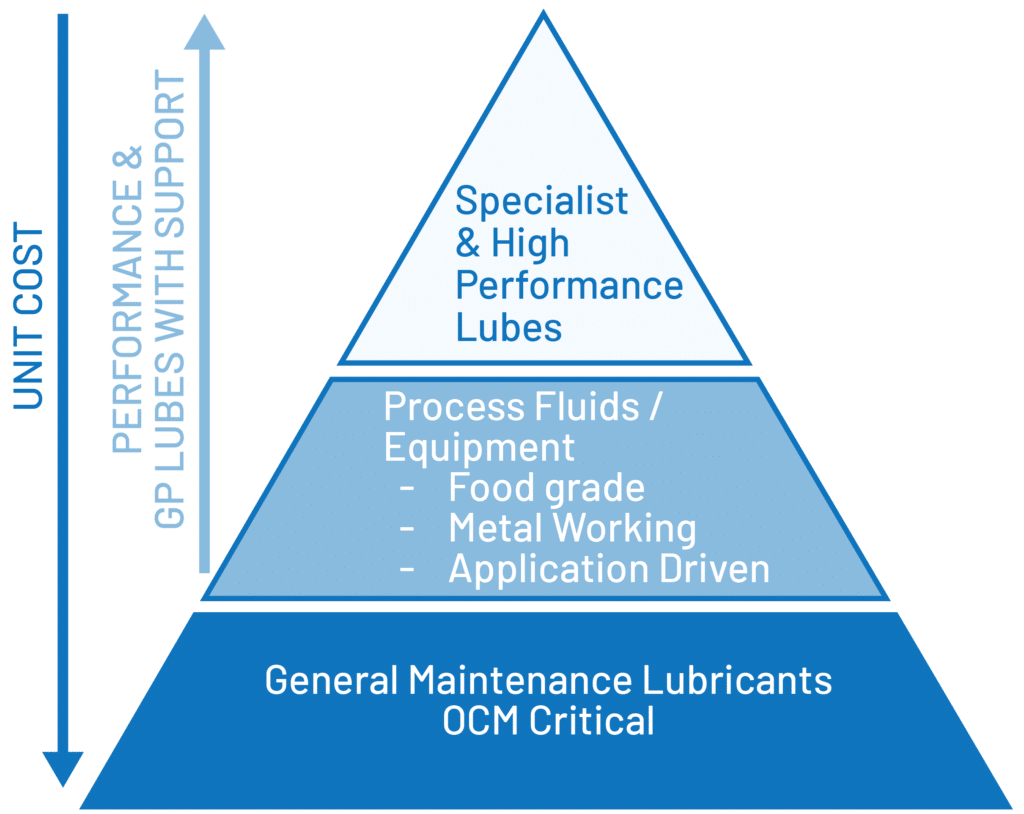

Doing Nothing Causes Wear and Tear and eventual premature failure. INDISOL applies 3 dimensional thinking to deliver effectiv

e S peciality Product Solutions that work and save money, these include but are not

limited to:

Indisol in their endeavour to provide you the BEST POSSIBLE LUBRICANTS SOLUTIONS apply a MULTIBRAND SUPPY STRATEGY. This allows us to cherry pick the best sol utions from credible global and local blenders to deliver the most cost effective supply position. INDISOL however only select from SUPERIOR TECHNOLOGY’S that deliver the most effective lubrication solutions you require. We manage the supply line by ensuring we have adequate stock of the selected technologies to meet you needs.

Quick Links

Contact

Copyright INDISOL PTY LTD © 2020